Do filter systems work?

Whether filter products are stating CFM, CADR or HEPA within their marketing, none of these can tell you how well a product will work in a “real world” environment. In reality, many filter products will repeatedly process the same air, creating a clean bubble of air around a unit but having no impact on air quality across the other side of the room.

What is CFM (Cubic Foot per Minute)

“Filter” systems operate by pushing or pulling air from a room through a filter to remove particles. Many filters quote CFM to tell you how much air is passed through the unit at its highest setting, but this gives no indication of efficiency. To put it simply, CFM does not tell you what is actually being filtered out of the air.

What is CADR (Clean Air Delivery Rate)

Developed in the 1980’s, CADR stands for Clean Air Delivery Rate. The CADR test generally consists of a unit operating at full speed for 20 minutes in a compact 13m2 (28m3) chamber, with additional fans on the wall and ceiling, where they measure how well the filter system reduces tobacco, dust and pollen. What is not shown from the test is what change in efficiency there would be after the unit operated for the next hour, day, week or month as filters become clogged and reduce in effectiveness. It’s very unlikely the room you are in right now is as small as a CADR test chamber, even less likely that you have a wall and ceiling fan operating. It’s not hard to understand that using the same unit in a larger room, without fans under natural airflow would produce very different results.

What is HEPA (High Efficiency Particulate Air)

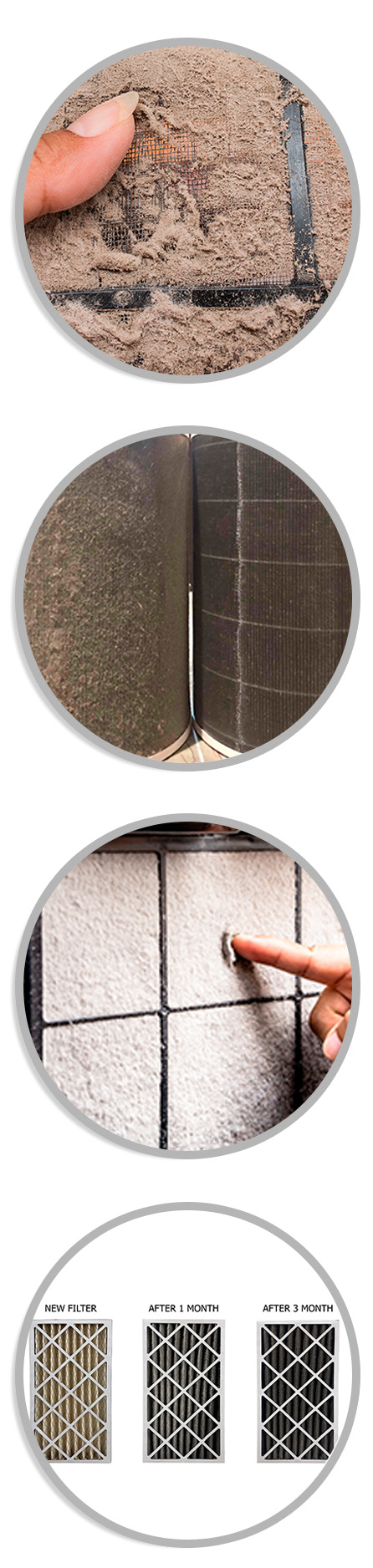

The most commonly known type of filter system would be a HEPA filter. HEPA stands for “High Efficiency Particulate Air”, as air moves through the filter, this type of system can theoretically remove 99.95% of airborne particles down to 0.3microns which would include dust, pollen and bacteria. HEPA filters are made up of thousands of fine fibres (usually polypropylene or fiberglass) arranged into a mat. Some HEPA filters claim they can be cleaned, but the majority advise regular replacement only. As with any filter system they naturally become more and more clogged from the first operation, so efficiency drops quickly.

Biggest concerns with filters:

Efficiency reduces with every minute of operation - the more particulates caught in the filter, the harder it is for air to move through and remove more.

Regular filter change required – replacing a filter every few months can be very expensive; some systems use combination filters which make this more costly and complicated.

Poor maintenance can increase risks – some filters can become breeding grounds for bacteria if not regularly changed, best case an unchanged filter is just no longer functioning.

Can create a clean bubble rather than a clean room – many units repeatedly process the same air.

No impact on air which does not pass through the unit - all contaminates, or odours would have to pass through the unit to be cleared.

Noise levels – many filter systems are simply too loud to have operating in a work, care or educational environment. This means they are turned off and have no impact.

Not designed for odours – some filter systems claim odour control, but we are yet to find any which work effectively.

Minimal real-world testing – CADR testing is a very small controlled environment and does not feature bacteria or germs, HEPA “efficiency” refers to what is captured by the filter, not its impact within a larger working environment.

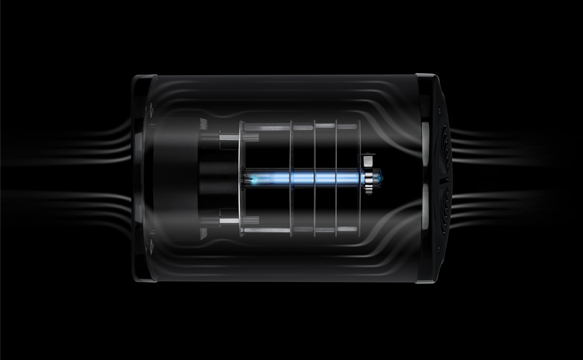

With Airsteril

AIRsteril systems produce tried and tested results, with a large bank of test data offering proven solutions for every indoor environment whether the major concern is reducing the risk from germs or eliminating unpleasant odours. Furthermore, many of our products are virtually maintenance free in the short term with only an annual lamp change required to maintain performance.